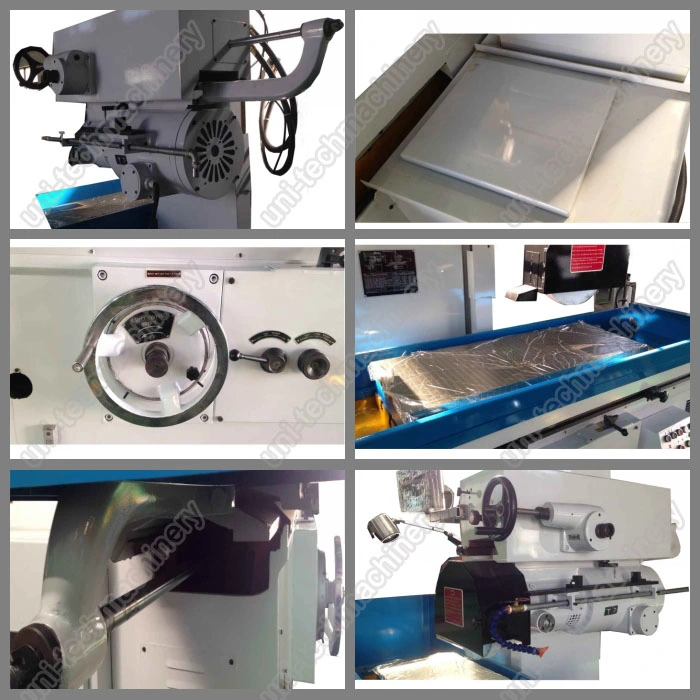

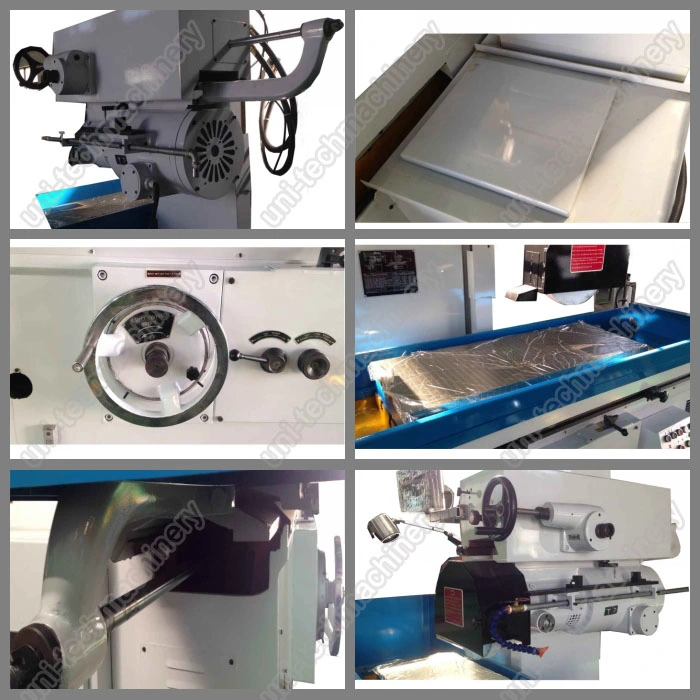

Horizontal wheel head moving surface grinder(M7163)

MAIN FEATURES:

3.Transmission: Worktable adopts one flat and one V guide ways, driven by hydraulic with smooth movement.

4.Grinding wheel adopts two sets of guide way, one is flat guide way for up/down moving.

Standard Equipment:

wheel flange, balancing arbor, wheel extractor,

coolant tank, working lamp, Tools, wheel dresser stand(not include diamond pen, standard grinding wheel, leveling wedge, leveling bolt, standard magnetic chuck

Optional Accessories:

wheel stand, Coolant tank with magnetic separator, coolant with magnetic separator and paper filter

WORKSHOP

Specification:

MAIN FEATURES:

1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting

2.Grind wheel head spindle front end adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity, specially for heavy-duty cutting.3.Transmission: Worktable adopts one flat and one V guide ways, driven by hydraulic with smooth movement.

4.Grinding wheel adopts two sets of guide way, one is flat guide way for up/down moving.

Another set is swallow tail guide way for back-forward movements, with manual feeding or

Auto-feeding by hydraulic cylinder.

5.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank.The temperature of the oil tank raises little so the thermal distortion of the machine is small.

6. Full lubrication system ensuring all guide ways smooth moving.

Auto-feeding by hydraulic cylinder.

5.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank.The temperature of the oil tank raises little so the thermal distortion of the machine is small.

6. Full lubrication system ensuring all guide ways smooth moving.

Standard Equipment:

wheel flange, balancing arbor, wheel extractor,

coolant tank, working lamp, Tools, wheel dresser stand(not include diamond pen, standard grinding wheel, leveling wedge, leveling bolt, standard magnetic chuck

Optional Accessories:

wheel stand, Coolant tank with magnetic separator, coolant with magnetic separator and paper filter

WORKSHOP

Specification:

| Model | Unit | M7130 | M7140A | M7140A x1600 | M7140A x2200 | M7150A x1000 | M7150A x1600 | M7150A x2200 | M7163 x1250 | M7163 x1600 | M7163 x2200 | |

| Worktable size(WxL) | Mm | 300x1000 | 400x1000 | 400x1600 | 400x2200 | 500x1000 | 500x1600 | 500x2200 | 630x1250 | 630x1600 | 630x2200 | |

| Max matching dimension(W x L) | Mm | 300x1000 | 400x1000 | 400x1600 | 400x2200 | 500x1000 | 500x1600 | 500x2200 | 630x1250 | 630x1600 | 630x2200 | |

| Max distance between spindle center line and worktable surface | Mm | 575 | 600 | 700 | ||||||||

| Longitudinal moving speed of worktable | m/min | 5-25 | 3-27 | |||||||||

| T-slot number x W | Mm | 3x18 | 3x22 | |||||||||

| Wheel head | Continuous feed speed | m/min | 0.5-4.5 | |||||||||

| Cross moving | Intermittent feed speed | Mm/t | 3-30 | |||||||||

| Hand wheel feed | Mm/gra | ------ | 0.02 | 0.01 | ||||||||

| Vertical Moving | Rapid speed | Mm/min | 400 | |||||||||

| of wheel head | Hand wheel feed | Mm/.gra | 0.005 | |||||||||

| Wheel Head | Power | Kw | 5.5 | 7.5 | 7.5 | |||||||

| motor | Rotation speed | Rpm | 1440 | |||||||||

| Total power | Kw | 8.63 | 11 | 13.5 | 12.25 | 13.75 | 15.75 | 13.75 | 15.75 | |||

| Max loading capacity of worktable (with chuck) | Kg | 470 | 620 | 1000 | 1380 | 700 | 1240 | 1410 | 1010 | 1290 | 1780 | |

| Chuck size(WxL) | Mm | 300x680 x1 | 400x1000 x1 | 400x800 x2 | 400x1000 x2 | 500x1000 x1 | 500x800 x2 | 500x1000 x2 | 630x1250 x1 | 630x800 x2 | 630x1000 x2 | |

| Wheel size (ODxWxID) | Mm | 350x40 x127 | 400x40 x127 | 400x40x203 | ||||||||

| Machine dimension(LxWxH) | Cm | 286x154 x203 | 311x182 x223 | 494x182 x223 | 674x182 x223 | 311x190 x242 | 514x190 x242 | 674x190 x242 | 399x220 x242 | 514x220 x242 | 674x220 x242 | |

| Machine Weight | t | 3.49 | 5.01 | 6.51 | 7.6 | 5.78 | 7.32 | 8.78 | 6.86 | 7.85 | 9.65 | |