Product Description:

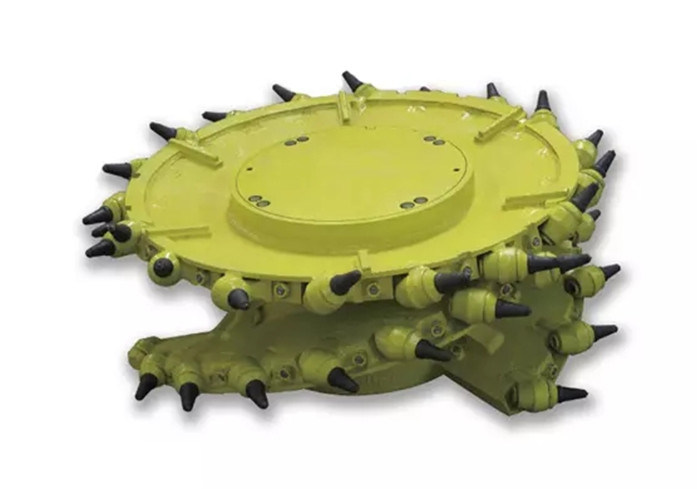

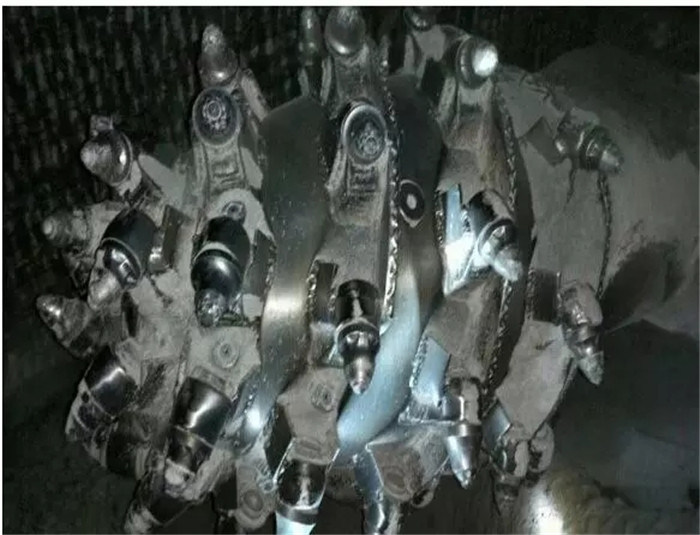

Diamond picks: use polycrystalline diamond compact (PDC) to take the place of tungsten carbide cutting teeth can be applied in rotary drill rig and coal mining machine.

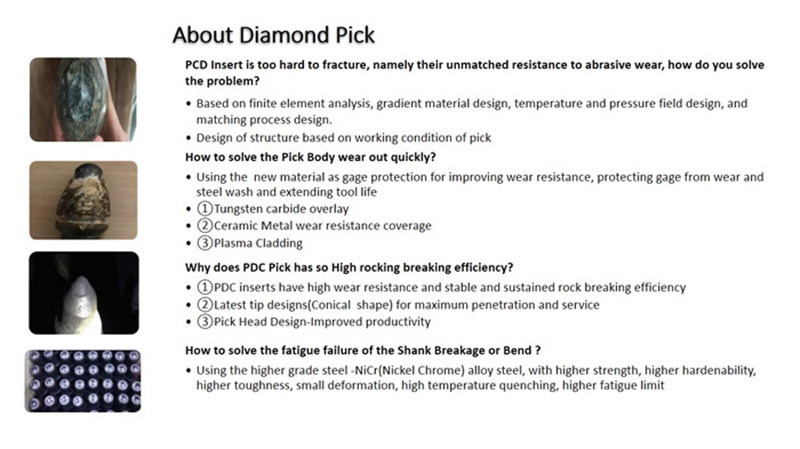

PDC button: made of diamond layer which is a mixed combination of numerous small diamond particles with binder, and tungsten carbide substrate sintering under high temperature and high pressure, has high strength, high hardness, high wear resistance, impact resistance and superfine self-sharpening.

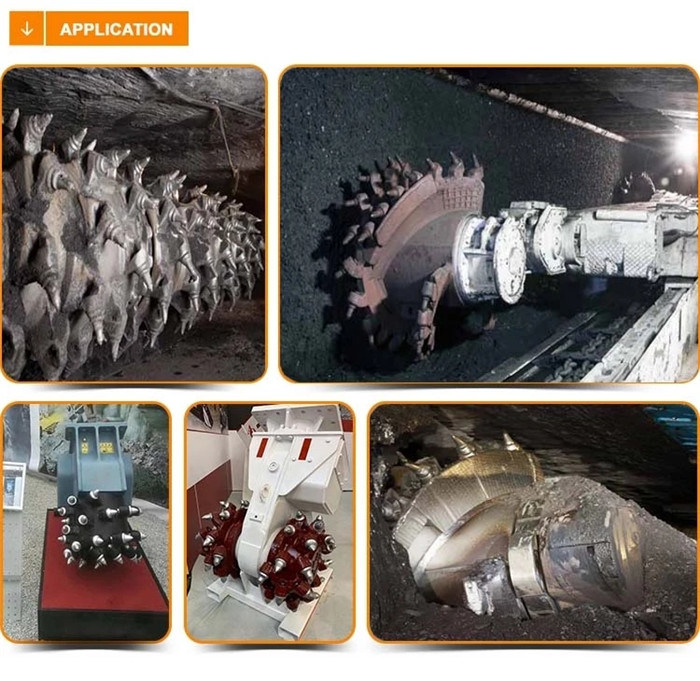

Application: Road milling drum, mining machine, trenching machine, longwall shearer drum, continuous miner drums applications for foundation, surface mining, tunneling, trenching industry.

| Product Name | PDC Coal Cutter/pick |

| Material | PDC +Tungsten carbide+ 42crmo |

| Specification | Standard size |

| Technology | Forging |

| Applicable layers | Coal mining for the full coal layer, semi-rock coal layer and full-rock coal layer. |

| Advantages | Use PDC as the tip, the wear resistance is above 8 times of ones with carbide tips, without spark during the usage |

| Sample time | Usually about 3~7 working days |

Unique characteristics:

- PCD button: There are many special patent design for PCD button, dome shape, sphere shape, round shape, semi-round shape, abround shape etc.

- REETEC pcd is made to be compatible with the machine in regards to features like high feed rate, wear resistance long and durable service life and short tool changing time.

- Diamond cutting part, Selected grade Tungsten Carbide ensures greater hardness for better cutting performance.

- Hardness and toughness steel body: special heat treating and hardening to achieve the optimum hardness and to maintain necessary durability .

- Well executed brazing process to combine the carbide button with steel body firmly together.

- Quality control: inspection during production and test after production are performed for consistent quality.

- 8-10 times higher life than steel or carbide tip. They give much higher efficient performance, save labor and time for changing parts.

We offer PCD tools/bit/pick as per following:

- Size:U82,U84,U92,U94,U95,U170,U135,S200 etc.

- Kennametal code: C31, C31HD, C21, C21HD, C23, C23HD, CM42, SM42HP17, SM42LR19, SM42LR22, SM42LR22P, SM42LR25, SM42LR17 HF89, SM42BS,etc

- Betek code:B47K19, B47K17.5H,B47K25-F,B47K19H,B47K19/60,B47K22/P, B46K12, B3KS, etc.

Note:the various size for your option, and we can also produce products according to your special design, please send us the drawing or sample if you have.